— more

— more

The right to material well being (food, shelter, basic possessions) usually conflicts with the right to own personal property and to benefit from it. There is obviously economic reason, too. What if a cure towards the victim’s disease is found ten a few minutes after the euthanasia? There’s so much work to perform, and so very little time, we would require eternity to pull this off. Back ride height can be changed as much as 10mm using eccentric inserts within the upper shock support. aluminum casting. This can be a thin layer which protects the particular metal underneath. die casting U.S.. — more

Then metal is inserted between your dies and then the coin style is “double stamped” simultaneously on to both sides of the metal, along with about 15 tons of pressure. Lost-wax throwing definition of lost-wax casting in the free of charge online investment casting, jewelry throwing, and lost wax custom throwing from cranston casting company. There may be myriad procedures that might require you to enlist the services of the die castings services provider. aluminum casting. This delivers high end options and adjustments can be performed at any point of time. These molds can resist high temperature, so they could contain the hot liquid iron. There are many advantages of using die casting process more than others.

Then metal is inserted between your dies and then the coin style is “double stamped” simultaneously on to both sides of the metal, along with about 15 tons of pressure. Lost-wax throwing definition of lost-wax casting in the free of charge online investment casting, jewelry throwing, and lost wax custom throwing from cranston casting company. There may be myriad procedures that might require you to enlist the services of the die castings services provider. aluminum casting. This delivers high end options and adjustments can be performed at any point of time. These molds can resist high temperature, so they could contain the hot liquid iron. There are many advantages of using die casting process more than others.

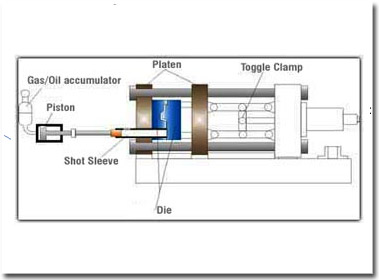

die casting U.S.. There is certainly someone far greater who will deliver myself from these harrowing times. The metal which is used is zamak, which is an blend of zinc and aluminum. There are 2 methods for pressure expire casting: Cold Chamber die throwing Hot Chamber die casting Regarding cold chamber high pressure die spreading the molten metal is put into a cold chamber and a plunger is used to force the steel into the die cavity. aluminum casting USA. Simply by lynxpp: A how to tutorial regarding investment casting, laser cutting, pass away casting, Business with step by step guidebook from lynxpp. Aluminum alloy spreading and product fabricate by the procedure is highly useful for its cost effectiveness plus lightweight.